Safety and Efficiency Guide for Demineralization Chemical Handling

Demineralization processes form the backbone of water purification across industries, but the chemicals that make this possible require stringent handling protocols to ensure safety and operational excellence. This comprehensive guide explores best practices for handling demineralization chemicals safely while maximizing efficiency in your operations.

Introduction: Why Demineralization Chemicals Deserve Respect

Demineralization chemicals serve as powerful agents in the removal of dissolved minerals and salts from water, transforming ordinary water into industrial-grade purity essential for countless applications. These chemicals-from strong acids used in cation resin regeneration to caustic solutions for anion beds-silently power everything from pharmaceutical manufacturing to power generation. Yet their seemingly benign appearance masks substances that can corrode metals, damage tissue, and create significant environmental hazards when mishandled.

The demineralization process involves removing minerals and salts such as sodium, calcium, iron, copper, chloride, sulfate, and nitrate from water through methods like ion exchange, distillation, or membrane filtration. When handling these chemicals goes wrong, the consequences extend beyond immediate safety concerns to operational disruptions and regulatory penalties.

For professionals working with these chemicals, understanding the full scope of risks isn’t optional-it’s essential for sustainable operations. The industrial stakes are high: demineralization chemicals feature prominently in incident reports, with consequences ranging from minor injuries to catastrophic system failures. Developing respect for these substances forms the foundation of a robust safety culture.

Demineralization Chemistry: The Backbone of Industrial Purity

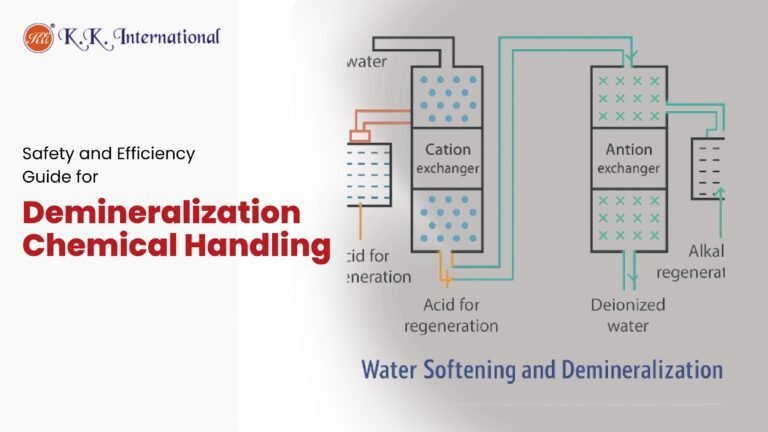

At its core, demineralization (DM) is the systematic removal of minerals and salts from water using specific chemical processes. Ion exchange represents the most widely implemented approach, utilizing specialized resins that swap unwanted ions in water with hydrogen and hydroxide ions. Modern DM plants using ion exchange can achieve impressively low conductivity values below 30 μmhos/cm, while Deionized (DI) water using Mixed Bed (MB) units can reach even purer levels below 5 μmhos/cm.

Membrane-based systems, particularly Reverse Osmosis (RO) combined with Mixed Bed technology, have gained popularity due to their automation capabilities and reduced manpower requirements. However, these systems aren’t without concerns-RO removes 92-99% of beneficial calcium and magnesium, creating water that may have long-term health implications according to WHO studies.

The chemistry behind regeneration involves powerful substances: sulfuric or hydrochloric acid for cation resin regeneration and sodium hydroxide for anion resin regeneration. These chemicals demand careful handling protocols as they represent some of the most aggressive substances used in industrial settings.

Understanding these chemical foundations enables safer handling by providing context for why specific procedures exist. The demineralization chemicals you handle daily aren’t arbitrary substances-they’re precisely selected agents with specific reaction mechanisms that enable industrial water purity.

The Risk Equation: What’s at Stake When Handling Goes Wrong

When demineralization chemical handling protocols fail, the consequences cascade across three critical dimensions: human health, environmental integrity, and operational continuity.

Human Health Impacts

The aggressive nature of regeneration chemicals poses significant risks to worker safety. Acids and caustics used in resin regeneration can cause severe chemical burns on contact, while improper handling of chemicals can lead to respiratory issues, skin irritations, and eye damage. The World Health Organization has extensively documented the health risks associated with improperly handled demineralization chemicals and their byproducts.

Perhaps most concerning, many incidents involve experienced personnel who have become complacent with daily handling procedures. Regular exposure without incident can lead to a false sense of security-until a single mistake causes catastrophic consequences.

Environmental Consequences

Improperly contained or neutralized demineralization chemicals threaten water bodies, soil quality, and local ecosystems. A single discharge of untreated regenerant waste can devastate aquatic habitats, with recovery potentially taking years. Regulatory penalties further compound these incidents, with fines regularly exceeding six figures for significant releases.

Operational Disruption

The operational impact of chemical incidents extends far beyond cleanup costs. Production downtime, equipment damage, emergency response expenses, increased insurance premiums, regulatory investigations, and potential legal liabilities create a compounding financial burden. Industry analyses suggest the total cost of a significant chemical incident typically runs 4-7 times the immediate visible expenses.

Most sobering of all: approximately 60% of chemical handling incidents result from procedural shortcuts, inadequate training, or insufficient maintenance-all preventable factors under management control.

Infrastructure for Integrity: Designing Safe Handling Systems

Facility design profoundly influences chemical safety outcomes. Purpose-built infrastructure for demineralization chemical handling incorporates several critical elements:

Containment Systems

Secondary containment represents the first line of defense against chemical releases. Modern designs incorporate chemical-resistant berms, sumps, and containment basins sized to hold at least 110% of the largest vessel’s volume. These systems prevent chemical spills from spreading and causing environmental damage or exposing workers to hazardous substances.

Material Compatibility

Chemical contact surfaces demand meticulous material selection. Improper materials can deteriorate rapidly, creating both leakage risks and contamination issues. Liquid transfer equipment (pumps, piping, pipe fittings, valves and instruments) in contact with process liquids or chemicals should be fabricated from materials that are chemically-resistant to the liquid streams. For strong acids, PVDF, high-grade stainless steels, or specialized elastomers provide necessary resilience, while caustic solutions require different material considerations.

Ventilation Architecture

Proper ventilation design prevents the accumulation of corrosive vapors that can damage equipment and harm personnel. Ion exchange resin safety data sheets specifically call for adequate ventilation when handling these materials. Engineered systems should maintain negative pressure in chemical storage areas, with airflow patterns directing potential releases away from workstations and common areas.

Transfer Systems

Safe chemical transfer systems minimize manual handling through closed-loop designs. Dedicated pumping systems with appropriate materials of construction, mechanical seals, and secondary containment considerably reduce exposure risks during routine operations. For systems requiring pressurized beds, proper design of tanks and associated equipment is essential to prevent leaks or failures that could expose workers to contaminated influent streams and/or backwash or reconditioning chemicals3.

Personal Protection Meets Professional Practice

The intersection of personal protective equipment (PPE) and behavioral discipline creates the foundation for daily chemical safety. Beyond basic compliance, leading organizations cultivate a protection-focused mindset.

Comprehensive PPE Programs

Effective protection extends beyond simply providing equipment-it requires systematic selection, training, maintenance, and verification procedures. Safety data sheets for ion exchange resins specifically note the requirement to “use personal protective equipment as required”5. For demineralization chemicals, tiered protection levels should match specific tasks and exposure risks:

- Level 1: Basic daily operations (chemical-resistant gloves, safety glasses, lab coat or apron)

- Level 2: Chemical transfers and sampling (face shield, chemical-resistant suit, appropriate respiratory protection)

- Level 3: Emergency response or confined space operations (full chemical ensemble with appropriate respiratory systems)

The Human Factor in Chemical Safety

Technical controls and equipment provide capabilities, but human behavior determines outcomes. Safety-conscious organizations implement behavioral systems that include:

- Task observation programs with peer feedback mechanisms

- Near-miss reporting systems that identify and address precursor behaviors

- Pre-task safety analyses for non-routine operations

- Regular simulation exercises for emergency scenarios

- Recognition programs for proactive safety behaviors

Training Beyond Compliance

Transformative training moves beyond regulatory minimums to build true competency. Most chemical incidents occur not from lack of knowledge but from failure to apply known procedures consistently. Effective training programs incorporate hands-on skill verification rather than just classroom time, scenario-based learning that develops decision-making capabilities, and refresher modules targeted to site-specific incident trends.

Smart Storage, Safer Sites

Modern storage practices prevent incidents before they begin while maximizing operational efficiency:

Chemical Segregation Principles

Proper chemical segregation prevents incompatible interactions that could generate heat, pressure, or toxic byproducts. Separate storage areas should be established for chemicals, flammable materials, and gas cylinders respectively6. For demineralization operations, strict separation must be maintained between:

- Acids and alkalis should never be stored together

- Strong acids should be kept separate from organic substances

- Oxidizing substances must be separated from oxidizable materials

Physical separation should include not just dedicated storage areas but also consideration of potential mixing during spill scenarios.

Storage Environment Control

Temperature and humidity significantly impact chemical stability and container integrity. Using a temperature-controlled storage area can prevent chemicals from freezing, which can cause containers to crack, or overheating, which can cause flammable substances to ignite. Storage areas should be:

- Easy to access

- Well-ventilated

- Temperature-controlled

- Sufficiently lit

Proper Container Management

To prevent leaks of liquids or fumes, chemical containers should be tightly sealed and kept off the floor on pallets. Containers should never be stored higher than eye level on racks, which should in turn be securely attached to the walls. Storage areas should have purpose-built drains and spillage barriers in place ahead of transfer.

Regular inspection of containers, particularly those holding corrosives and acids, is essential to detect signs of leaks or corrosion before they become significant problems.

The Transfer Touchpoint: Loading, Unloading, and Dosage Safety

Chemical transfer operations represent the highest-risk touchpoints in the demineralization process, demanding systematic approaches:

Loading and Unloading Protocols

Bulk chemical deliveries introduce external variables that require structured management. Safe transportation of chemicals requires using correct vehicles, ensuring that vehicles are properly marked, and having emergency equipment (such as fire extinguishers) on board7. Facilities should implement:

- Dedicated unloading areas with secondary containment and emergency equipment

- Verification procedures for both chemical identity and quality

- Standardized connection systems that prevent cross-contamination

- Driver safety orientation and site-specific requirements

- Communication protocols between operators and delivery personnel

Metering and Dosing Safety

Precision in chemical addition not only optimizes treatment effectiveness but also prevents safety incidents. Automated dosing systems with redundant control mechanisms can reduce the risk of human error during chemical addition processes.

Transfer Equipment Integrity

The mechanical components of transfer systems require systematic inspection and maintenance. Ion exchange systems consist of pressurized beds (tanks, pumps, and piping) that can leak or fail if not properly maintained3. Regular inspection protocols for hoses, connectors, and transfer equipment help ensure system integrity and prevent unexpected failures during operation.

Emergency Response Is a Culture, Not a Checklist

Effective emergency management transcends documentation to create a response-ready culture:

From Plans to Preparedness

While emergency response plans fulfill regulatory requirements, true preparedness emerges from regular simulations that test both procedures and decision-making, scenario-based drills that introduce unexpected complications, and coordination with local emergency responders before incidents occur.

Spill Response Capabilities

Chemical spill management requires both equipment readiness and personnel capability. Areas where corrosives and acids are stored must have spill kits or secondary containment areas readily available in case of emergency. A comprehensive approach includes:

- Strategically positioned spill kits matched to specific chemical types

- Neutralization materials appropriate for site-specific chemicals

- Personal protective equipment staged for immediate access

- Drainage control systems that prevent environmental release

- Communication systems that function during facility emergencies

Medical Response Integration

Chemical exposure scenarios demand specialized medical responses. The World Health Organization has documented that consuming demineralized water or being exposed to demineralization chemicals can cause cardiovascular disorders, tiredness, weakness, and muscular cramps. Emergency response plans should include:

- First aid protocols specific to site chemicals

- Availability of Safety Data Sheets for emergency medical personnel

- Transportation plans for chemical exposure victims

- Relationships with medical facilities experienced in chemical exposures

Efficiency in Motion: Streamlining Without Compromising Safety

Safety and operational efficiency need not conflict-properly designed systems enhance both simultaneously:

Process Optimization

Streamlined processes reduce both exposure risk and operational costs. Membrane-based demineralization systems like RO+MB have become more popular because of automation and less manpower requirements for the regeneration process. Other efficiency improvements include:

- Standardized work procedures that incorporate safety elements

- Batch preparation systems that minimize manual handling

- Ergonomic design of workstations and control panels

- Workflow analysis to eliminate unnecessary chemical handling steps

Maintenance Integration

Preventive maintenance programs should explicitly incorporate chemical safety elements, including integrity testing of chemical containment systems, calibration of safety-critical instrumentation, and inspection protocols for chemical transfer equipment.

Performance Metrics That Matter

Meaningful metrics drive continuous improvement in both safety and efficiency:

- Leading indicators like near-miss reporting and procedure compliance

- Chemical exposure monitoring data

- Process efficiency measurements

- Regeneration chemical consumption per volume treated

Digital Monitoring and the Future of Chemical Handling

Technological advances are transforming chemical handling risk management:

Real-Time Monitoring Systems

Advanced sensor networks provide unprecedented visibility into chemical systems, including continuous leak detection in storage and transfer areas, remote monitoring of chemical parameters, and integration of personal monitors with facility alarm systems.

Automation Advantages

Automated systems remove humans from high-risk activities. Robotic sampling systems eliminate routine exposure risks, while automated chemical delivery systems with verification safeguards reduce the potential for human error during critical operations.

Data-Driven Decision Making

The accumulation of operational data enables smarter risk management through analysis of near-miss patterns to identify system weaknesses, correlation of process variables with safety outcomes, and continuous refinement of safety protocols based on operational data.

KK International’s Commitment to Responsible Chemistry

As leaders in demineralization technology, KK International recognizes that product excellence extends beyond performance to encompass the entire lifecycle, including safe handling:

Engineering Safer Systems

Our design philosophy integrates safety from concept through implementation, with chemical delivery systems that minimize manual handling, regeneration processes with reduced chemical consumption, and automated controls that prevent operator exposure.

Ongoing Partnership

KK International views customer relationships as long-term safety partnerships, providing regular technical bulletins on emerging best practices, customized training programs for operating personnel, and site assessments that identify improvement opportunities.

Beyond Compliance

Our commitment extends beyond minimum regulatory requirements to include independent third-party testing of safety systems, transparent sharing of performance data, and continuous improvement based on customer feedback.

Conclusion: Safe Handling is Smart Business

The integration of safety into demineralization chemical handling represents more than regulatory compliance-it embodies sound business strategy. Organizations that master safe chemical practices consistently demonstrate superior performance across multiple dimensions:

- Reduced downtime and maintenance costs

- Lower insurance premiums and regulatory oversight

- Enhanced workforce engagement and retention

- Stronger community and stakeholder relationships

- Improved operational consistency and product quality

The most successful operations recognize that safety and efficiency are not competing priorities but complementary forces that, when properly aligned, create sustainable competitive advantage. By embracing the principles outlined in this guide, facilities not only protect their people and environment but position themselves for long-term operational excellence.

In the final analysis, safe chemical handling isn’t just the right thing to do-it’s the smart way to operate.